What is the prime mover in drilling rig?

What is the prime mover in drilling rig?

The prime mover in a drilling rig is the main engine or power source responsible for driving the drilling equipment and operations. It provides the necessary force to rotate the drill string and penetrate into the earth's surface to extract natural resources such as oil and gas.

The choice of prime mover in a drilling rig depends on various factors, including the type of rig, depth of drilling, and the type and size of the drill bit. The most commonly used prime movers are diesel engines and electric motors.

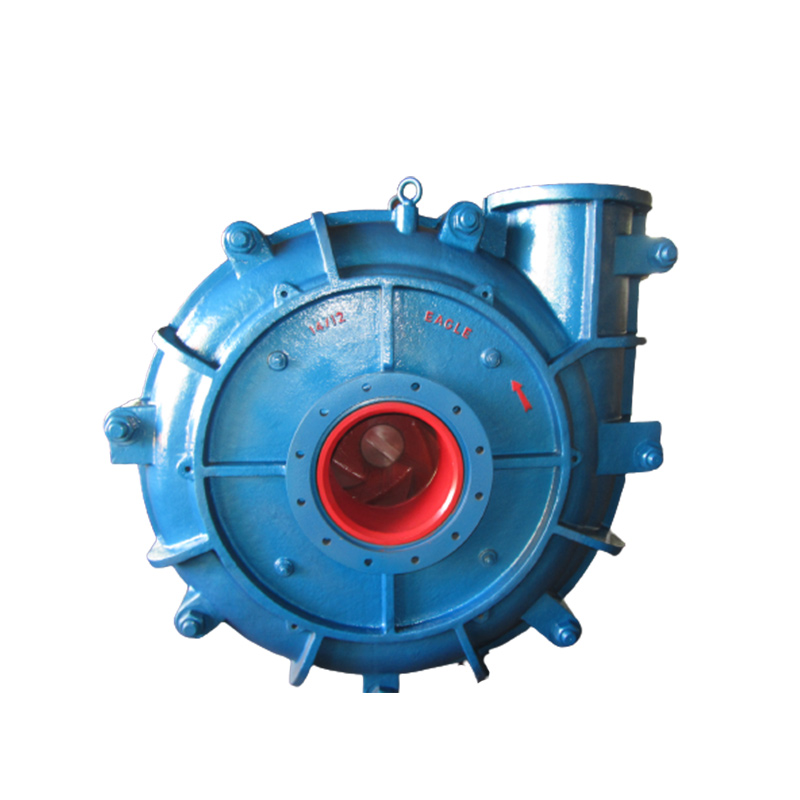

Diesel engines have been widely used in the drilling industry due to their high torque output and reliability. They are especially suited for offshore drilling rigs where a constant and reliable power source is crucial. Diesel engines provide the necessary power for driving the rotary table, drawworks, and mud pumps.

Electric motors, on the other hand, are commonly used on land-based drilling rigs where a more consistent power supply is available. They offer a cleaner and quieter alternative to diesel engines, reducing emissions and noise pollution. Electric motors are usually connected to a generator, which converts electrical energy into mechanical energy to drive the drilling equipment.

Additional resources:What is a piston pump used for?

Choosing the Right Cryogenic Valve for Industrial Processes

What is the difference between iron pipe and ductile iron pipe?

Guide to Choosing the Best Miniature Bearings

Unlocking the Power of Diesel Engines: A Comprehensive Guide

What is tank mounted compressor?

What Is Difference Between Ball Valve and Globe Valve?

The choice between diesel engines and electric motors as prime movers also depends on the environmental regulations and requirements of the drilling location. In some areas, strict emission standards may require the use of electric motors to minimize the impact on air quality.

The prime mover plays a significant role in the efficiency and effectiveness of drilling operations. The power generated by the prime mover is transmitted through the drilling system to create rotational force, allowing the drill bit to penetrate the earth's layers. The prime mover's ability to provide sufficient torque and rotational speed ensures efficient drilling and reduces downtime.

Additionally, the selection of the appropriate prime mover can also impact the safety of drilling operations. The prime mover should be able to operate under demanding conditions, such as extreme temperatures and high altitudes, without compromising performance or reliability.

In conclusion, the prime mover is the main engine or power source in a drilling rig, responsible for providing the necessary force to drive the drilling equipment. The use of diesel engines or electric motors as prime movers depends on factors such as rig type, drilling depth, and environmental regulations. The choice of prime mover has a significant impact on the efficiency, effectiveness, and safety of drilling operations.

If you are looking for more details, kindly visit wellhead api 10d ball screw gate valve manufacturer, mud cleaner desilter, k55 steel.

Additional resources:What is a butterfly valve used for?

What is the investment casting process?

Investment Casting vs. Die Casting: Which Is Right for Your Application

What Is the Fuel Efficiency of Caterpillar Diesel Engines?

How does a Photocatalyst Filter work in air purifiers?

Parts of a ball valve

What is the stator in a DC motor?

Related Articles

Comments