Why is firebrick so expensive?

Firebrick, a remarkable construction material known for its exceptional heat resistance, finds widespread application in various industries, including furnaces, kilns, and fireplaces. However, one thing that often perplexes people is the relatively high cost associated with these humble bricks. In this blog post, we will delve into the factors responsible for the premium pricing of firebrick and shed light on its intrinsic value.

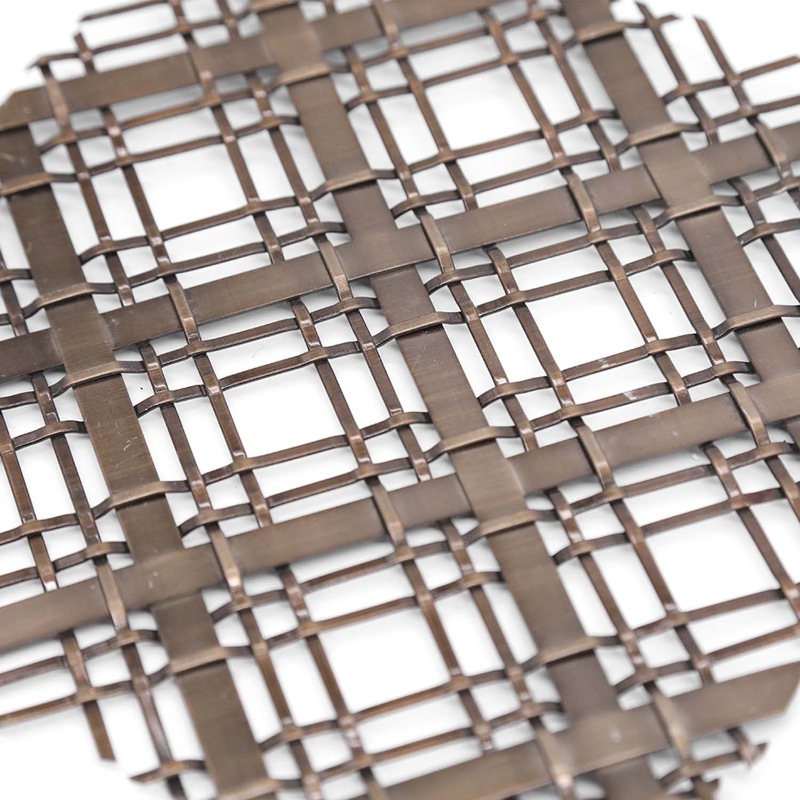

Understanding the Composition:

Before uncovering what contributes to the price of firebrick, let us first unravel its composition. Firebrick is primarily made of refractory ceramic materials, typically consisting of alumina (aluminum oxide) and silica (silicon dioxide). The precise combination of minerals and the manufacturing process determine the quality and heat resistance capabilities of firebrick. It is this unique composition that makes it a go-to choice for environments subjected to extreme temperatures.

Exceptional Heat Resistance:

One of the primary differentiating factors setting firebrick apart from regular bricks is its ability to withstand intense heat. The melting point of firebrick can exceed 3000°F (1650°C). Unlike common bricks that would crumble under such conditions, firebrick remains structurally intact, making it ideal for lining furnaces and kilns, promoting enhanced insulation and heat retention.

Specialized Manufacturing Process:

The production of firebrick is a complex and elaborate process that requires technical expertise and precision. The methods involved in manufacturing firebrick typically include carefully selecting raw materials and subjecting them to high-temperature firing and controlled cooling. These stringent manufacturing protocols contribute to the durability and robustness of firebrick, ensuring its resilience even under the harshest conditions.

Limited Availability of Raw Materials:

The raw materials used in firebrick production, particularly high-quality alumina and silica, are not abundant resources. The extraction and refinement processes require specialized techniques, making the supply chain for firebrick raw materials both limited and costly. The scarcity factor, coupled with the rising demand for firebrick in numerous industries, reinforces its expensive nature.

Research and Development:

To continually improve firebrick's properties and adapt to evolving industrial needs, ongoing research and development efforts are essential. These endeavors demand significant investments, including scientific studies, testing, and innovation, leading to advancements in firebrick quality, performance, and longevity. Consequently, these added costs are reflected in the final price of firebrick.

Handcrafted Expertise:

The art of crafting firebrick involves skilled craftsmanship and meticulous attention to detail. Experienced artisans employ their specialized knowledge and techniques to ensure consistent quality and precision during the manufacturing process. The human touch in firebrick production adds value and guarantees a trustworthy product, making it a worthwhile investment for industries prioritizing durability and reliability.

Stringent Quality Control Standards:

To meet the stringent demands of high-temperature environments, firebrick undergoes rigorous quality control checks during and after production. These tests include inspecting dimensional accuracy, thermal conductivity, and overall strength. The commitment to maintaining these quality standards adds to the cost, ensuring that every firebrick meets the desired specifications and safety norms.

Environmental Considerations:

Unlike regular bricks, firebrick manufacturing processes often involve more energy-intensive and environmentally impactful procedures. Given the ever-increasing focus on sustainable practices, manufacturers have to invest in eco-friendly processes, such as employing cleaner fuels or adopting energy-efficient technologies. These measures further accentuate the cost of firebrick production.

Conclusion:

As we dig deeper into the factors underlying the seemingly high price of firebrick, it becomes evident that its value extends far beyond its basic composition. From the scarcity of raw materials to the specialized manufacturing techniques and continuous research, every aspect contributes to the firebrick's worth. Its unmatched heat resistance, handcrafted precision, enduring reliability, and strict quality control make it an indispensable material in industries where extreme temperatures are a constant challenge.

By comprehending the intricate details of firebrick production and acknowledging the investments involved, we appreciate the true essence and significance of its price tag. Firebrick exemplifies the notion that sometimes, excellence can only be achieved through expertise, dedication, and a commitment to quality, all of which come with their associated costs.

For more information, please visit castable refractory cement, refractory mortar, high alumina bricks.

Related Articles

Comments